PROCESSES

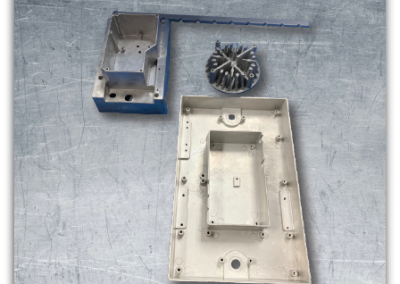

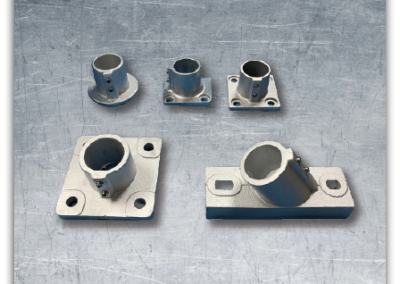

DIE-CASTING

This high-pressure molding results in a more unified part. Generally, clean surface finish and good dimensional accuracy (as good a 0.2% of the casting dimension). The precision of Die-Casting allows for minimal secondary machining in many cases. Die-casting is intended for high volume usage. Tooling costs are higher due to the construction of the molds. Specific materials/alloys available upon request.

DIE-CASTING

This high-pressure molding results in a more unified part. Generally, clean surface finish and good dimensional accuracy (as good a 0.2% of the casting dimension). The precision of Die-Casting allows for minimal secondary machining in many cases. Die-casting is intended for high volume usage. Tooling costs are higher due to the construction of the molds. Specific materials/alloys available upon request.

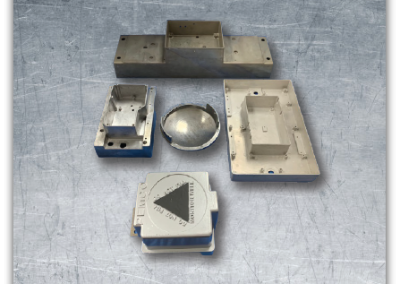

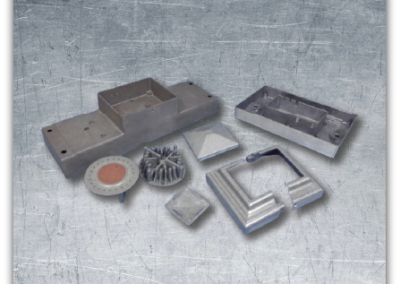

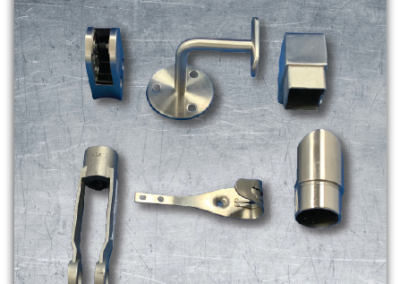

INVESTMENT CASTING

INVESTMENT CASTING

Also known as the lost wax process, Investment Casting allows for intricate shapes with near-precision accuracy. Parts produced by Investment Casting often do not require further machining unless very precise tolerances are required. Specific materials/alloys available upon request.

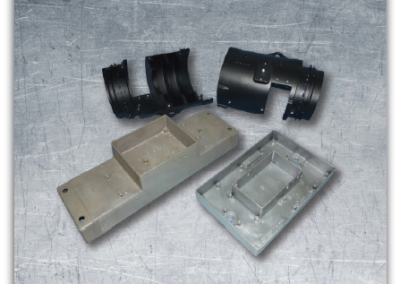

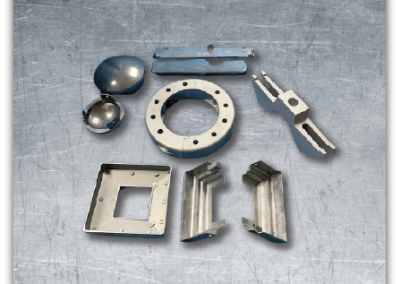

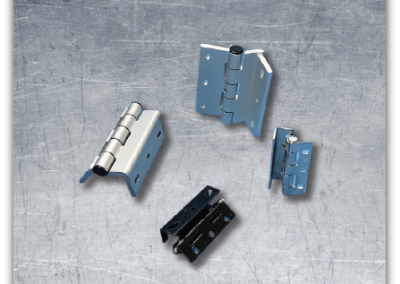

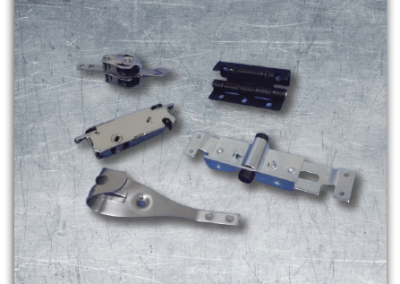

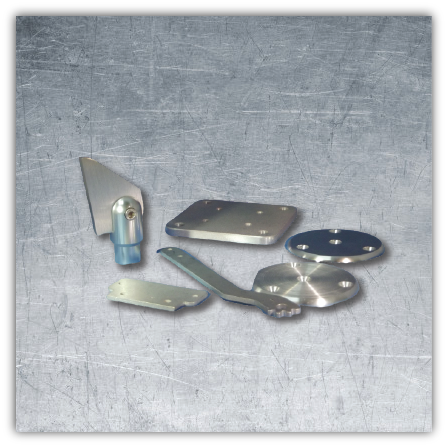

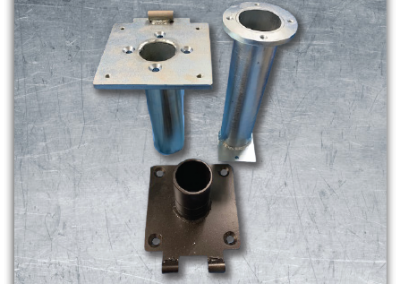

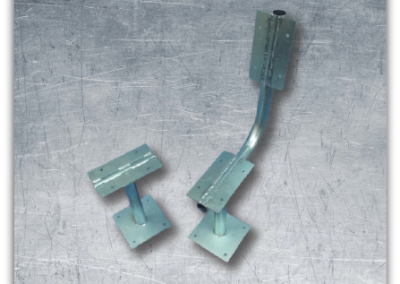

Sheet metal forming is utilized to structure metal into specific shapes and sizes. The common techniques include bending and forming, rolling, stamping, punching and welding. Additional capabilities include deep draw stamping and cold headed forging. Specific materials/alloys available upon request.

SHEET METAL STAMPING

SHEET METAL STAMPING

Sheet metal forming is utilized to structure metal into specific shapes and sizes. The common techniques include bending and forming, rolling, stamping, punching and welding. Additional capabilities include deep draw stamping and cold headed forging. Specific materials/alloys available upon request.

GET IN TOUCH

If you are looking for product quality with consistent and reliable supply, please contact us now.

worldindustrialproducts@gmail.com

call

(305) 231-0221

Find Us

5803 NW 151 Street, Suite 204

Miami Lakes, FL 33014